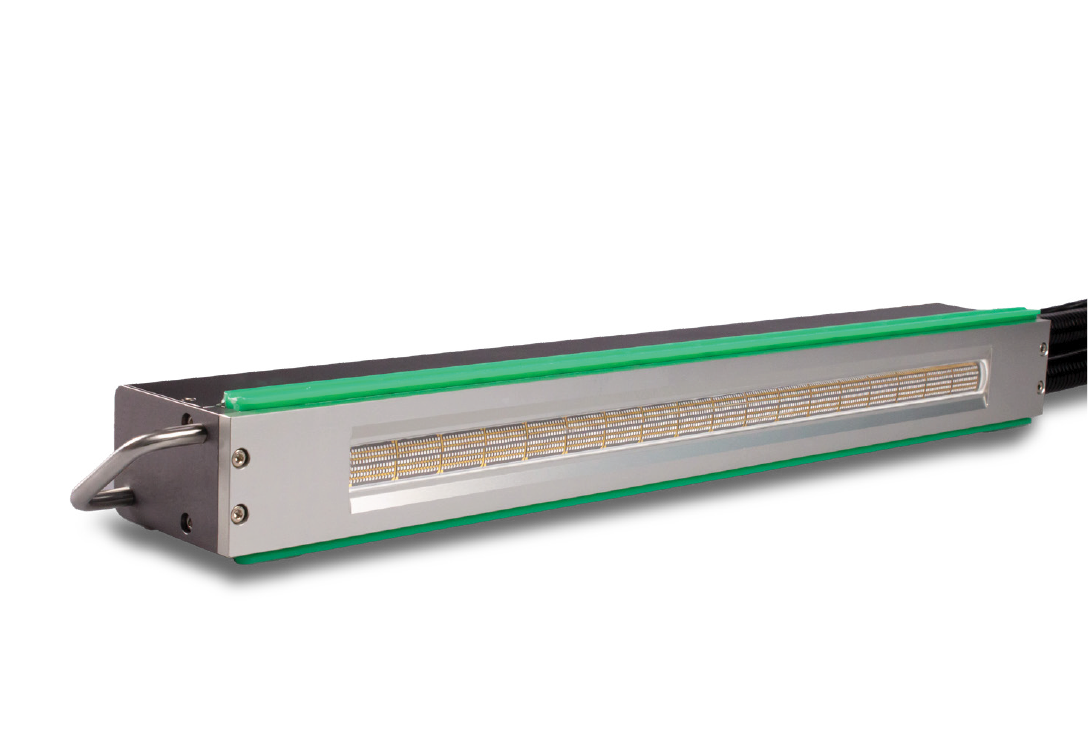

LUXTREME

LUXTREME

Features

High speed, up to 200m/min

Suitable for heat-sensitive substrates

Instant on/off with no energy used in stand-by mode

Sustainable ozone and mercury-free system

30-60% fewer LEDs required to achieve same radiant intensity as other comparable systems

30-50% higher radiant intensity, up to 25W/cm2

Special LED adapter allows easy integration on existing mountings

Up to 50,000 hours LED life

Up to 720mm lamp length, scalable in 24mm steps

Benefits

Productivity and quality improvements

Thanks to the high performance of the LuXtreme LED UV curing system, productivity and quality improvements are significant. Not only can press speeds be increased, but job set up and make ready times can be reduced as there is less material distortion due to heat.

Improved substrate stability also results in a more controlled ramp up to production speeds, and it is often possible to achieve the required colours much faster with Fujifilm’s high performance CuremaX flexo ink system. Add to that improvements to the system reliability with much lower press down time, productivity gains can be significant. Quality also becomes more consistent as the impact of the heat from the UV lamps is reduced, resulting in better registration and less substrate distortion.

Savings in energy, materials, labour and waste

Due to the reductions in power required for the LED UV lamps, cost savings can be made across the production process. The energy savings are significant, but material usage and waste are also reduced, and the lower maintenance required to support the LED UV curing system results in a much lower number of replacement parts, with lower associated labour costs.

Environmental improvements

The LuXtreme LED UV curing system has significant benefits to both the working environment and the environment as a whole. Energy use is reduced, with no energy used in stand-by mode, and the lower amounts of materials used and waste produced all benefit the environment. The working environment for operators is also improved, with many undesirable factors eliminated or reduced, including heat from the conventional UV lamps, ambient noise and odour

CuremaX flexo inks

Fujifilm’s CuremaX ink ranges include dual cure products designed to work alongside the LuXtreme LED lamp systems with the added benefit of curing under conventional UV lamps. Each CuremaX ink range incorporates a range of colours, process inks, metallic shades and specialist products, and are all formulated to meet the changing demands of the flexo industry. The manufacturing of these products ensure a consistent, high quality result time after time with vibrant strong colours.

Key benefits that CuremaX inks offer include:

Low viscosity press ready colours

High colour density

Adhesion to a wide range of synthetic substrates Including top coated PE & PP, PVC, PET, some thermal papers, metallised foils and most commonly available papers

Suitable for a wide range of applications including self-adhesive labels and unsupported films for sachets and pouches

Over printable with thermal transfer ribbons and cold foil adhesives

Good hot foiling properties

Dedicated Pantone® formulation matching system

Flexo sleeve white for shrink sleeve applications